We are one of India's major CNC Parts manufacturers in the Small and Medium Scale (SME) sector, with more than 10 equipment.

In Rajkot, Gujarat, we operate out of a large 3700 sq. ft. built-up space. We are India's leaders in CNC precision Parts manufacturing, handling highly important work down to 3 microns, With a reputation in engineering dating back over seven years

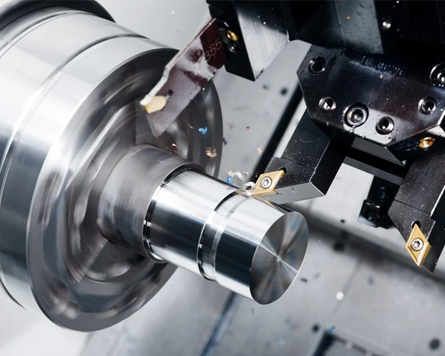

Our capabilities vary from large-scale production to small-scale job production. For high accuracy and hard part turning, we have equipment from Spinner and Harding super precision CNC turning. With the use of a variety of machining procedures,

we produce wide range of Precision Machined Components and Assemblies

We are a fully equipped factory with complete inhouse mold-producing capabilities,ranging from revolutionary equipment to CNC, VMC, auto parts, and engine components such as pistons, shaft, gears, crankshaft, and camshaft

For all of our privileged clients, we ensure to deliver the best VMC Machine India, by employing the newest forms of tools and technologies in milling operations.

To provide the services, our highly-trained VMC Machine professionals use cutting-edge technology and tools. Our experts are ready to create a variety of components in VMC job work based on the client's description and requirements for any industry sector.

Engimold Techno’s manufacturing capabilities cover the full spectrum of precision engineering products. By combining top-of-the-line machinery, highly skilled professionals, and a quality-focused management approach, we turn even the most complex engineering designs into high-quality products.

Our machine shop is designed to support both mass production and batch production efficiently. Engimold Techno Engineering offers a range of CNC Turning Machine, CNC Vertical Machining Centre with 4th Axis capabilities, all equipped with advanced control systems for precise and reliable production work.

We have the capability to design and manufacture process fixtures and specialized tools in-house, supported by a strong design team. Our experienced engineers take a proactive approach, ensuring minimal time is required for new product design and development.

Our CNC machining capabilities are ideal for producing high-quality prototypes and small production runs. Whether testing a new product design or manufacturing custom components, we deliver parts that perform reliably under real-world conditions, enabling quick iteration and design refinement.

• Rapid Prototyping - Quickly test and refine designs before full production.

• Custom Components – Tailored parts to meet specific project needs.

• Low-Volume Runs –Cost-effective solutions for smaller quantities.

When it’s time to scale, we’re ready. Our high-volume CNC machining services offer consistent quality and efficient production cycles to meet the demands of larger projects. With our scalable infrastructure, we produce high-precision parts at volume without sacrificing quality.

We go beyond machining to offer a range of finishing services, from polishing and anodizing to painting and plating. We also provide assembly support, so your parts are not only precisely machined but fully ready for integration into your final product.

•Anodizing, Plating, & Polishing - Enhance durability and aesthetics.

• Assembly & Sub-Assembly – Ensures components fit and work seamlessly together.

• Quality Assurance –Each part undergoes thorough inspections to meet exacting standards.

| MACHINE NAME | DESCRIPTION | Qty |

|---|---|---|

| 3-axis vertical machining center | Make : Ace Micromatic (AMS) Model : ACER DOUBLE- PALATE Controller : SIEMENS Range : 800 x 510 x 500 Loading Capacity : 500 kg | 1 |

| 3-axis vertical machining center | Make : JYOTI (HURON DESIGN) Model : VMC-850 NVU Controller : SIEMENS Range : 800 x 510 x 510 Loading Capacity : 1000 kg | 1 |

| 3-axis vertical machining center | Make : JYOTI Model : VMC-850 Controller : SIEMENS Range : 800 x 510 x 500 Loading Capacity : 500 kg | 1 |

| 4-axis vertical machining center | Make : JYOTI Model : :RDX 20 Controller : SIEMENS DM Range : 800 x 510 x 510 Loading Capacity : 500 kg | 1 |

| CNC Turning center | Make : Ace Model : :VX-200 Controller : FNUC Range : 200 DiaX500 Length | 2 |

| Convetional Lathe Machine | Make : Indian Range : 200 DiaX500 Length | 2 |

| Piller DrillMachine | Make : Indian Range : 20mm drilllX200 Length | 1 |